Supplier of power generation and energy technologies, GE Energy, has introduced a fuel-blending technology for its gas turbines that will enable operators to lower fuel costs by reducing the amount of natural gas fuel required by the turbines. The new system cuts cost and boosts efficency, the company say.

Fuel flexibility and efficiency are critical issues facing gas turbine owners and operators today. Jeffrey Goldmeer, F-platform fuel flexibility manager for GE Power & Water said: “Our new fuel blending solution allows operators to use process gas to displace a portion of the natural gas fuel, thereby reducing natural gas usage and fuel costs.”

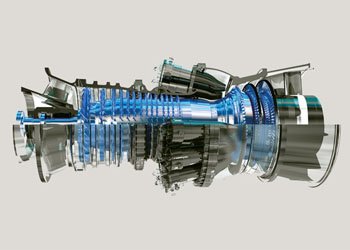

This new technology enables the blending of up to 5% hydrogen into a GE dry low NOx 2.6 combustion system. Users can take hydrogen gas that is a byproduct of the process as part of the fuel mix for a 7FA Gas Turbine.

Fred Moore, global director of manufacturing & technology energy, Dow Chemical said: “Working with GE, we were able to use excess process gas more efficiently, which has reduced the amount of fuel required to power the turbines. The startup of the system on the first unit went as planned and now is operating, meeting our expectations.”

GE’s fuel-blending system for the 7FA allows the use of waste gases to generate more efficient power instead of having to use the process gas in a lower efficiency system, such as a duct burner. It also can reduce the need to dispose of the process gas by flaring.