The owner of chocolates like Aero, KitKat and Smarties has generated savings worth £350,000 through its energy bills and incentives a year after installing a waste-to-energy plant.

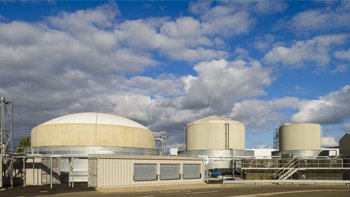

The facility at Nestlé’s Fawdon confectionery factory generates renewable energy by converting 200,000 litres of feedstock – such as wash waters from the site – every day.

The biogas fuels a combined heat and power (CHP) plant, which produces 200KW of electricity – or 8% of the factory’s power needs – used in the confectionary production process.

The installation by Clearfleau has helped cut Nestlé’s annual electricity bill by around £100,000 and also receives payments of around £250,000 every year through the Feed-in Tariff scheme.

Inder Poonaji, Nestlé’s Head of Sustainability said: “On-site treatment of production residues will help us reduce the wider environmental impact of our business and meet our sustainability goals. By working with Clearfleau, we continue to reduce our carbon footprint and generate value from food production residues.”